What steps are required for gearbox testing?

How strict is the product testing of Comfortex? Today, let's take a look at what steps are involved in the testing of our gearboxes before they are put into storage.

\ | /

★

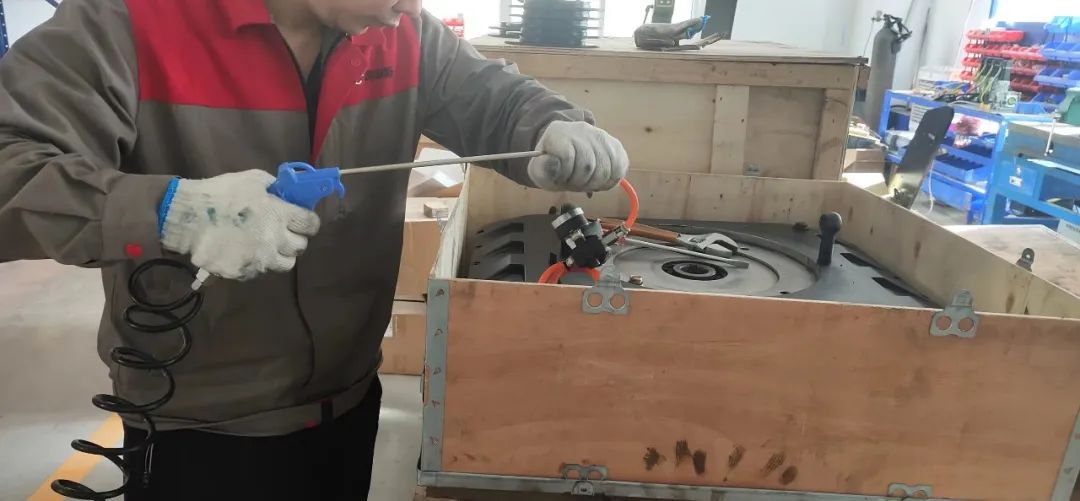

Pressurize the gearbox for pressure testing, the main purpose of this link is to check whether it is leaking.

\ | /

★

2. The gearbox with no problems in the initial inspection is lifted by a lift and placed in the area to be inspected.

\ | /

★

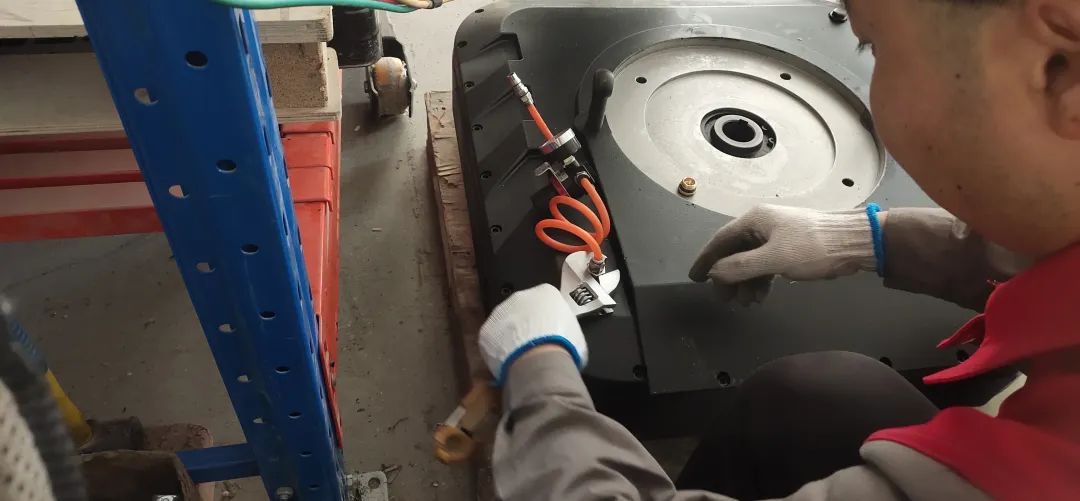

3. After placing the pending inspection area, first of all, check the chassis for any problems, followed by the product model to be recorded and registered in the inspection table.

\ | /

★

\ | /

★

\ | /

★

Get the latest price? We'll respond as soon as possible(within 12 hours)

more products

News

Products

Featured Products

Contact Details